If you want to track your shipments using the Internet of Things (IoT), the big question is about whether to go the capital expenditure (CapEx) or Operational Expenditure (OpEx) way when implementing new systems.

A quick search on Google “GPS vehicle trackers” can be quite tempting. You’re staring at hundreds of search results with devices that will cost you $300 or less, not including shipping costs.

CapEx seems attractive, doesn’t it?

Hang in there!

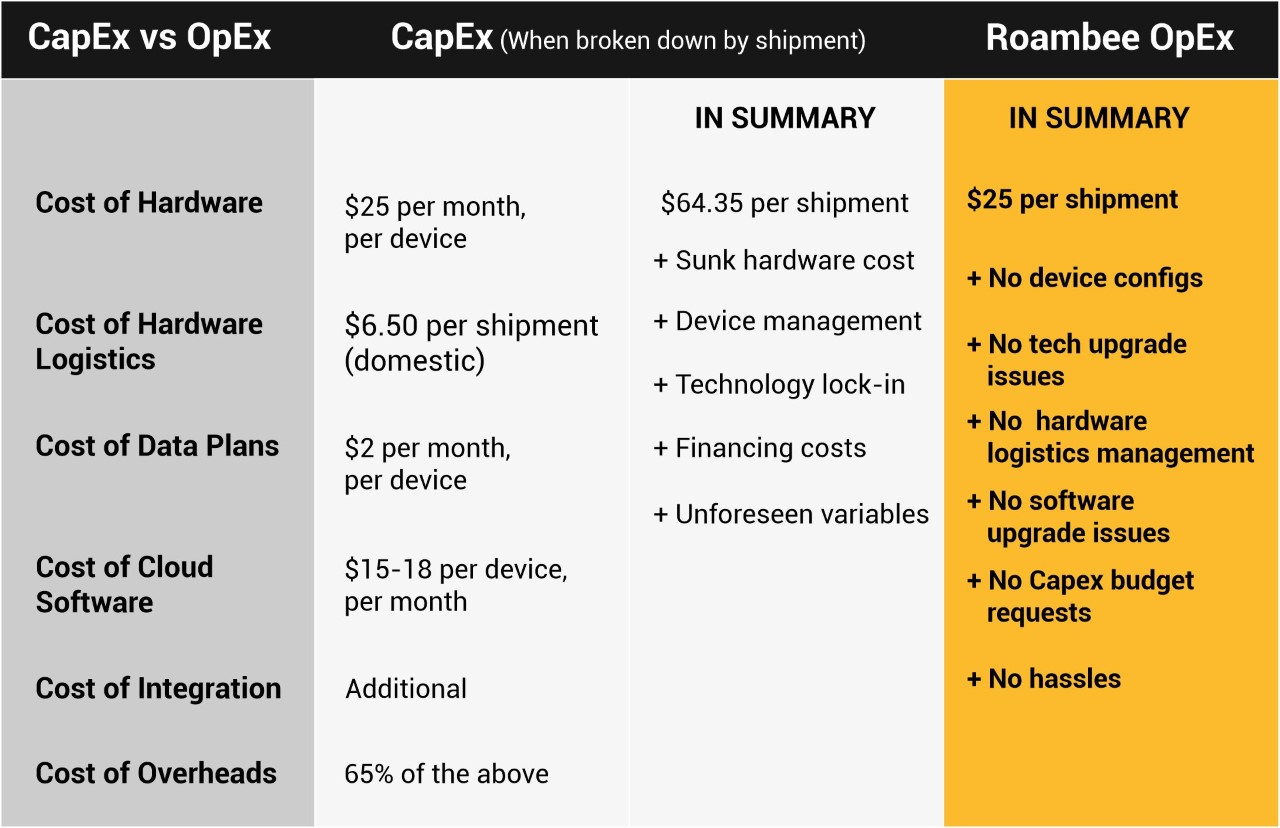

The device cost may look tempting, but when you break down the solution into its bare basics and then sum it up to a “per shipment cost,” it will work much higher than a Roambee-type OpEx model.

The other aspects to consider are scale and financial predictability.

When you have leaner and tighter months in terms of shipment volumes, especially when your assets are lying idle and your finance team is questioning their utilization. They like numbers, and you do too, as every strong organization is built on scale, financial predictability, lower borrowings, agility, and higher ROI.

Therefore, to get an accurate picture in terms of numbers, let’s compare a standard CapEx model of shipping tracking which would cost less than $100* per shipment to monitor at a container, pallet, or package-level against a fully-managed OpEx services model like Roambee. Roambee's fully-managed service bundles hardware, global data connectivity, cloud-based software, and support value-added services into a simple per-shipment price.

*Note: Pricing stated is based on the specific type of shipment monitoring package that customers are using, geography, and other local variables. Roambee pricing varies based on application, geo, and scale.

So, how did CapEx end up being so expensive?

Let’s drill-down into each of these line items.

The Real Cost of CapEx

1 — Cost of Hardware

The IoT game begins with collecting good data.

So, let’s look at a how much the shipment tracking hardware to do that would cost. An exhaustive Google search followed by testing samples of the 100+ vendors including Sendum, Onasset, Tive, Cartasense, and others would land you at a device cost of about $300, if you are looking for something reliable with enough battery life, minus any sensor functionality like temperature, humidity, or pressure.

This works out to $12.50 per device per month over a 24-month device lifecycle and it doesn’t include the cost of setting it up or configuring the devices.

2 — Cost of Hardware Technology Upgrade

![]()

A 24 or 36-month lifecycle for your devices is only on paper.

What if a better technology comes out in 12 months or less? In the cell phone industry today, there is a significant upgrade every year, and IoT hardware is not very different. Do you want to say no to a drastically beneficial technology that will come your way in less than 2 years, especially if it can make your organization smarter and more efficient?

Geo-political changes are happening faster than ever as well, countries are launching their own GPS satellites, new technologies like Nb-IoT and Sigfox are taking over the market, and hardware needs to be replaced, and replaced fast.

A classic example lies in cold chain monitoring. Companies started implementing GPS vehicle tracking systems to get real-time data of their vehicles, to compliment data loggers providing temperature at the end of every trip. Suddenly, IoT package-level monitoring solutions like the BeeBeacon Cold Chain tracker enabled visibility into both with a single-solution.

If you take a 1-year device technology lifecycle, the cost per month per device is actually $8.33. There is no salvage value because nobody is going to buy outdated technology in the IoT space.

3 — Cost of Hardware Reverse Logistics

![]()

Here is where the math starts hitting you the most, especially when you opt for an unbundled model.

For calculations purposes, let’s say your average shipment is 7 days in length. You would need to budget at least 3 days for reverse logistics. Add a day for the device to get picked up and another 2 days in transit back to your location, and another 2 days to re-charge its battery, and you will end up accomplishing about 2 shipments per month with each device.

The cost of reverse courier pickups may sound inexpensive, but the cost of coordinating and managing the reverse logistics of hundreds or thousands of devices is not.

- Cost of device use per trip: $12.50 per device

- Cost of courier per device per trip: $4

- Cost of labour @ $30 per hour: $2.50 per device even if 12 devices are processed per hour

The cost of reverse logistics alone work out to $6.50 per shipment. That means tracking each trip, all inclusive, costs you $19 per shipment.

4 — Cost of Data Plans

![]()

Cost of a data plan is about $1.50 - $2 per month per device, but there is more you need from your telco. What about the following?

- When your cellular signal is weak and unable to transmit a data packet, you still need to be able to locate your device. Telcos offers what they refer to as Location Based Services (LBS) where they tell you the last tower that your device contacted.

- When your existing cellular provider cannot offer you coverage in an area where your shipment is passing through, you need to rely on an alternative cellular carrier.

Therefore, bundling the networking solution into the service is more art than science, and doing it yourself or relying on systems integrators may not cut it, especially at a global scale.

Overall, once you've added the Telco costs, you're looking at $20 per device, per trip.

5 — Cost of Software

![]()

This component is almost always opex as most software is now offered as a service. Not counting the cost of developing the software which may run in millions of dollars, the cost of hosting the software in the cloud, data archiving, uptime monitoring, mapping API license, SMS and email server for sending alerts and such, and you're looking at a software cost of around $15 - $18 per device, per month.

This makes the per shipment operating cost $35 - $38.

6 — Cost of Integration

![]()

Systems integrators make most of their money here. When you go CapEx, here are the places where you will spend repeatedly on:

- Software updates

- Device upgrades

- Additional functionalities you have requested which affect an existing integration

7 — Cost of Overheads

![]()

Now add your team spending time in charging the devices, running device diagnostics, firmware upgrades in addition to the support costs, maintenance costs, training costs. Industry standard is no lesser than 65% to cover these costs, and even if you are not running these overheads, a vendor or hired resource is.

You're now at $64.35 per shipment, excluding the cost of integrations, if any.

Net Cost of CapEx

![]()

It's close to $64.35 per shipment.

Plus:

- Sunk hardware cost

- Device management

- Technology lock-in

- Financing costs

- Unforeseen variables

Net-Net — The Hidden Discount of OpEx

![]()

Compare the $64.35 CapEx cost with Roambee's $25 per-shipment OpEx model.

Plus:

- No devices to configure

- No missing out on technology upgrades

- No device logistics to manage

- No missing out on software upgrades

- No future bugs to worry about

- No justification of capital expenditure in your budgets

- No hassles

The OpEx bundle builds on seamlessly with value-added services like a 24x7 control tower, on-site personnel, or anything else that may be helpful towards your business case, eliminating the hassles of piecing together a solution that takes so much effort to just make it work.

So, how does Roambee make this happen?

It boils down to economies of scale and a whole lot of automation. For example, Roambee’s network optimization algorithms route devices to other customers once they finish a trip to maximize utilization. Our platform is built to service upwards of a billion messages per day, and at this scale, the cost of APIs and software building has reached a point of inflection. Our algorithms also predict network dead-zones that your device could run into, and it works out an alternate mode or network to save data plan costs.

So, the next time an IoT vendor proposes a CapEx model, think again!

The device cost may seem low, but you WILL end up spending 2x or 3x that when it comes to implementation.