Reusable shipping assets like containers, pallets, crates, totes and bins could be bleeding your supply chain budgets if not used optimally. Let us find out how you can manage these returnable packaging items better and rid your supply chain of non-performing assets (NPAs) using Bluetooth Low Energy (BLE) beacon tracking technology.

Across industries, companies use returnable packaging materials such as containers or pallets to preserve the quality of their materials shipped, as well as to display them on retail shelves. If you are using such returnable containers, pallets, crates, totes, or bins, often referred to as “Returnable Transport Packaging (RTPs),” “Returnable Transport Items (RTIs),” “Returnable Shipping Assets,” or “Reusable Shipping Assets” or just “RSAs,” they could be impactingyour overall supply chain costs – if they are not managed optimally.

A lack of optimal management of returnable packaging often leads to hidden costs. You may not know of the financial impact arising from inefficient use of these returnable shipping assets, unless you are using an end-to-end tracking technology to identify the areas where you could be sinking your funds. Most of the times, these costs remain hidden and are an area of the supply chain which is often overlooked for optimization by most companies.

Read why pallets could be a sneaky hidden cost in your supply chain.

Tracking your reusable or returnable supply chain assets isn't important just for optimization; it'll also shed light on the depth and magnitude of inefficiencies that may be bogging your supply chain today.

BLE, when used with a GSM or Wi-Fi hotspot, is an Internet of Things (IoT) solution that monitors your returnable packaging end-to-end —both in your warehouses, and when in-transit. BLE-based IoT solutions use beacons or tags that can be attached to your asset (RSAs), and a gateway hotspot that reads such beacons in its vicinity, all of which work together to monitor your assets within a “virtual zone.” These virtual zones could be set up anywhere, within your warehouse, on a moving truck, within a rail wagon, or even on an airplane. The data is collected and analyzed to provide you with insights about the location, condition, and behavior of your totes, bins or pallets, data that you can use to optimize your supply chain.

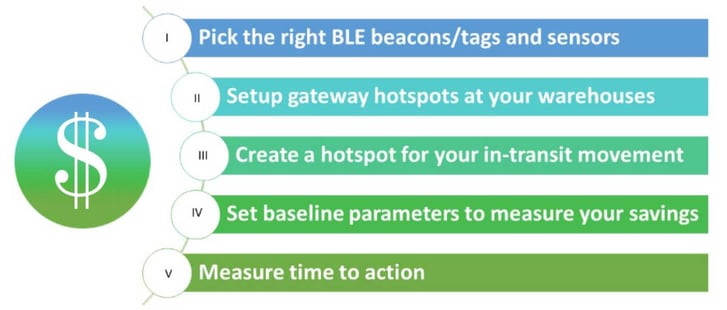

The question now becomes - With a viable solution in place, how can you monitor these RSAs to ensure return on investment? Here are the 5-steps to get you fully functional with your BLE based tracking solution and reap its benefits!

5 Steps to Save On Returnable Containers & Pallets by Tracking Using BLE

1. Pick the right BLE beacons/tags and sensors

BLE beacons or tags (these terms are often used interchangeably), can provide you more than just the “last seen” location of your returnable containers or pallets. BLE beacons also have the ability to carry inbuilt sensors including shock, temperature, and light depending on the service provider.

For example, with fragile shipments like glass or electronics, you may want to go with beacons that measure shock and capture incidents of impact including drops, collision, or other physical mishandling that may damage your goods. If you are shipping frozen goods like fish or meat, you may want to have temperature sensors to ensure your goods do not suffer quality damage or bio-contamination due to a temperature excursion in-transit.

Sensors are important to a beacon, from the perspective of both managing your returnable shipping assets better, and monitoring the condition and health of your shipments. For example, light sensors are helpful for sensing if the package has been tampered with or if it has been removed from the pallet.

2. Setup gateway hotspots at your warehouses

Hotspot gateways for a low energy beacon based IoT solution can be portable GSM devices or quite simply, your smartphone!

To secure your warehouses, it is best to go with portable GSM devices like the “Bee” rather than a smartphone, so that there is always a gateway hotspot present on the floor to monitor pallets moving inside, outside, and around your warehouse. By having these GSM devices fixed in their respective locations, you can also create “virtual zones” within a large warehouse to identify pallets or containers instantly when you need them, rather than manually searching the entire warehouse.

Once you have identified the zone where your required pallet is, use a BLE Beacon Finder App to locate where the specific pallet is, and identify it among your inventory pool – without having to physically search every item in that zone.

Creating virtual zones in your warehouse and using a BLE Beacon Finder app will give you a bird’s eye view of where all your returnable shipping assets are (both in your and your customer’s warehouses), and help you locate them within seconds from when you need them.

3. Create a hotspot for your in-transit movement

Now that you have secured your warehouses with your gateway hotspots, it is time to ensure that your pallets are monitored in your warehouses, as well as when they are moving between your factory, vendor, and customer locations.

You can do this in two ways by using:

i. A Fixed Gateway Hotspot

You can use a portable device reader like the Bee, which travels with your goods. This is most helpful when you are hiring vehicles from the market (also called “market vehicles”) or when your goods move across air, sea, rail, or multiple modes of these transports.

Your reliance on reporting information from the carrier of the goods is greatly minimized when you use this method. You have got visibility and data throughout the route without depending on your carrier or the vehicle driver.

ii. Mobile as a Gateway Hotspot

If you are operating your own or dedicated fleet, you can have your driver’s mobile phone double as a gateway hotspot. The advantage here is that you are not managing any additional hardware that is riding with your goods, other than the beacons that are already attached to your pallets, containers, bins or crates.

4. Set baseline parameters to measure your savings

Having figured out the right tags for your reusable packaging and the gateway hotspots for your warehouses and your transport logistics, you need to establish the parameters on which you plan to estimate your savings from this tracking initiative.

The majority of your savings will come from essentially four areas:

i. Reducing returnable container loss and associated insurance costs

This can be achieved by preventing aging, damage and theft of your returnable containers. With BLE you can set real-time alerts to warn you when a pallet moves out of your chain of custody (preventing theft) or when it ages beyond a certain number of days at a particular location (preventing aging).

For example, if your returnable transport packaging (RTP) costs $50 and your insurance company pays you 90% of your claim during a loss with a deductible of $5 per claim, then the total savings for you is $10 per RTP by preventing loss. If you are losing 100,000 pallets every year, this is an immediate savings of $1 million for your business.

ii. Utilizing your returnable transport items (RTIs) better

This essentially means more revenue per returnable transport items through lesser idle time and time spent in return journeys or back-hauling.

For example, say a reusable container or pallet costs you $0.50 per day to rent and you use it for 300 days in a year. By bumping your “per-pallet” usage up to 360 days in a year, your pallet is put to work for another 60 days, which means you’re not wasting the $30 you would have if your rental was sitting idle somewhere. While $30 may seem like a small amount when compared to the $150 you’re already “utilizing”, always remember there’s a cumulative effect. Efficiency, or excess, for that matter, has a tendency to snowball with time and scale. If you were running an operation where you’ve rented out 250,000 pallets, you’d be making better use of $7.5 million of your shipping asset budget by scaling the more efficient utilization of that measly $30.

iii. Saving “Lost Days in Shipping” & Associated Working Capital Due to Unavailability of RSAs When Needed

Not having an RTP or container to ship, when needed, can cost you big!

For example, if you had 5,000 consignments each worth $250,000 and you save a 2-day delay on each, the savings on your Working Capital Interest at an interest rate of 5% is $68 per consignment or $340,000 annually.

iv. Saving “Lost Days in Shipping” & Associated Detention Cost

Every extra day your truck spends waiting for you to load your consignment (owing to lack of pallets, bins or totes) is an additional day of detention billed to your company.

If your transporter/shipper is charging you a per day detention cost is $25 for their truck and you are using 5,000 trucks annually, saving just 20% of this (that could be caused by lack of the right kind of pallets, crates or totes) can amount to $25,000.

5. Measure time to action

Once you have established your savings parameters, it is all about acting on anomalies, and doing so promptly to get results!

Set the following alerts on your IoT solution portal and ensure your teams are ready to respond.

Some important alerts to pay attention to are:

- RSAs that are in a particular location beyond scheduled aging times.

- RSAs/RTPs/RTIs that are no longer in the vicinity of the warehouse, or are not located on the truck which they are supposed to be on, could indicate that it is lost, misplaced, or even stolen.

- Response time on shipping pallets or containers to another warehouse which needs it. This can impact location surplus or shortfalls in your network. Better ability to measure the efficiency with which the warehouses in your network are recycling or recirculating your returnable containers can have a significant impact on your bottom line.

Before you start tracking, it is important for you to get an accurate estimate of how much you can potentially save by using this 5-step implementation process. Use our free online calculator to get started!

Get Internal Buy-ins to Implement Tracking by Speaking Their Language

Numbers speak louder than words, but presenting the savings to your stakeholders in a relevant, contextual language that they will understand is equally important to earn buy-ins and make the initiative truly successful.

Most likely, not everyone in your firm is looking at cost-savings alone! For instance, your sales teams could be more concerned about timely and effective response to customers and competitors than in just cutting costs for your supply chain.

So how can you translate these savings you calculated into business benefits for your respective stakeholders?

Here is a summary of the top benefits for each of your company functions spanning across shipping times, detention, working capital, and bottom-lines that arise out of managing your returnable containers and other shipping assets better.

| Your Teams | Your Promise |

| Logistics | Pallets are always available for shipping - no dispatch delays, detentions, or time spent in filing insurance claims. |

| Supply Chain | No disruption in supply chains and a new avenue to reduce spends. |

| Quality | Surety that the goods being shipped have the right protective packaging, and the conditions like (temperature, humidity or pressure) are maintained. |

| Sales | No sales orders lost due to late arrivals, faster market response. |

| Finance | Lesser Non-Performing-Assets (NPAs) on the books and lower Total Logistics Cost (TLC) as a percentage of revenue. |

| Technology | Ability to accurately audit the company's assets and a new avenue to improve productivity through automation. |

| Executive Team | Increase in share-holder and bottom-line value due through: 1. Lower Total Logistics Cost (TLC) as a percentage of revenue and, 2. Competitiveness: Response time, meeting delivery SLAs (higher NPS scores). |

Why BLE, and Not RFID, For Monitoring Returnable Shipping Assets

BLE beacon technology is similar to RFID. It has tags and readers too like RFID, but has a lot of flexibility regarding cost, implementation and scalability when compared to RFID.

The most important advantages of BLE beacons are their cost and the fact that your smartphone can double up as a gateway hotspot to read your BLE beacons (also known as BLE tags) when needed – which also enables in-transit visibility for returnable shipping assets.

| Parameter | RFID Technology | BLE Beacon Technology |

| Cost | RFID readers and tags are expensive due to their proprietary nature. They cannot be manufactured at economies of scale. |

Cost-effective because Bluetooth ports are available even on smartphones and thus manufacturing of tags has reached economies of scale. Example: Apple’s iBeacons |

| Internet Connection Requirement | Readers cannot be moved easily as they need to be wired to the LAN of the warehouse or require a Wi-Fi connection or WAN. | BLE tag readers, known as gateway hotspots, are mobile phones or mobile GSM-based devices - therefore it can communicate anywhere - in the warehouse or in-transit. This provides it the ability to monitor indoors, outdoors, and in-transit without needing any internet cables or Wi-Fi. |

| In-Transit Monitoring |

You cannot use RFID readers easily (even the portable ones) to track containers or pallets which are in-transit – while carrying your goods or making their return journey. Either their battery life is not optimized (due to the high-energy nature of RF waves and the lack of the inbuilt SIM card feature in most readers). Therefore, any loss or inefficiencies in the management of pallets in-transit cannot be accounted for. |