Are you implementing an IoT solution in your organization for supply chain tracking? Do you envision a digitization initiative for supply chain tracking leading to the improvement of your bottom line? What is the risk of its failure? Does your IoT supply chain tracking solution provider have what it takes to make you successful? In this blog, I will talk about the five pillars which can determine the success of your supply chain tracking IoT implementation.

The author delivered a talk on this topic at The Economic Times Global Logistics Show supported by The International Supply Chain Education Alliance and World Trade Center Pune, India.

The Internet of Things (IoT) concept began as a simple idea of connected devices. For example, your car rental company installs a GPS in the car to track the car’s location in real-time. Over time, IoT evolved from devices being able to collect and communicate data to devices being able to process data and make decisions. Now systems can know if you are speeding in your rental car and can send you an SMS warning that there will be a cost overage unless you slow down! Have you ever wondered what happens behind the scene in such an IoT supply chain tracking application to enable the closing of such decision loops in seconds?

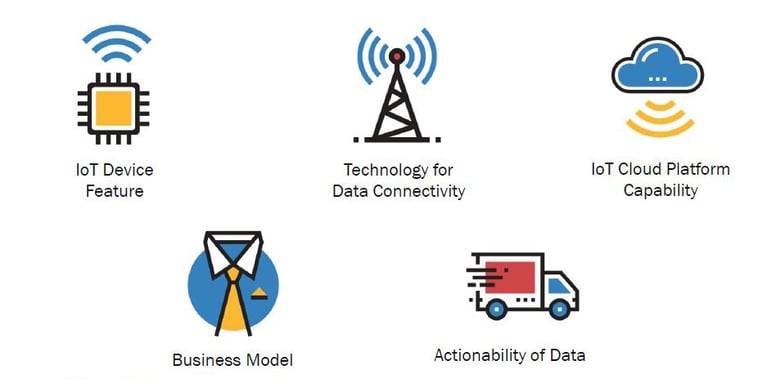

In essence, there are five pillars at work in any supply chain tracking IoT solution throughout the cycle of identifying a problem and fixing it in real-time. Be it tracking your just in time (JIT) shipments or monitoring the construction equipment you have leased, understanding these five pillars, what they do, and how they are interdependent, can improve your chances of achieving the desired tracking outcome.

1. IoT Device

The device is your means of collecting data. It is your eyes and ears where you cannot use your own. Hence, it is critical to ensure that the IoT device you use for your supply chain tracking is versatile and can collect all the data that is meaningful to you. Some features to evaluate are:

- Is it wireless? Don’t depend on your vehicle or asset to power the device. A lack of power could result in an interruption of data collection.

- Does it last the entire application? You will need to be sure it works whether it is for a 3-year asset financing period or a 90-day ocean shipment.

- How versatile is it when it comes to collecting data? You will want on-demand ability to add condition and environment sensors - for example, temperature sensors to monitor your vaccines in transit or light sensors to indicate tampering for shipment of iPhones.

- Can it be remotely configured and re-configured? It is important to be able to change reporting intervals when an unexpected or critical exception occurs.

- Can it monitor at a package or item level? The location and condition of every parcel or small asset can be crucial for theft or reducing inefficiencies in the supply chain with enhanced IoT-based supply chain tracking.

2. Connectivity

A mobile phone serves as a good analogy for the importance of connectivity. Your phone may have the best camera resolution and the smoothest touchscreen, but it is useless when you do not have a telecom tower nearby to make that one important phone call to inform your boss that you won a big sales contract! Connectivity determines how efficiently the device collects and transmits data in real-time to the cloud for quick decision-making for your supply chain tracking effeicency.

Features to look for in an IoT solution include:

- Multi-telecom global connectivity

- Device's ability to store data during an absence of signal and buffer it later

- Cross-platform communication across Bluetooth, WiFi, NB-IoT, and Long Range (LoRa) networks to ensure that data is always available for timely and accurate analytics.

3. IoT Analytics Platform

The technology platform is the brain behind the decision-making process. Let’s think about some of the characteristics of smart, successful individuals or teams, and draw parallels to an IoT analytics platform:

- Smart people frequently research before making a decision. An IoT platform, too, must have the ability to consume large quantities of information from the IoT devices and multiple external data sources and use this information for decision-making.

- Successful people are often visionaries. They can anticipate the future and plan for it accurately. The same goes with the IoT platform, it should give you insights into past behavior and inform your foresight on future actions. For example, to determine the best route for a consignment, the IoT platform should consider past driving patterns, current weather, the shipment's condition and en-route traffic conditions to provide recommendations on routing.

- Similar to how collaboration makes the team succeed, the right IoT platform must provide a vast number of APIs to integrate with enterprise software such as SAP and Oracle to seamlessly marry data sets.

4. Business Model

The lifecycles of today’s cellphones are less than a year. Such is the pace at which technology is evolving. The cost of new technology is also continuously falling due to economies of scale. The same applies to IoT devices and platforms. If your IoT vendor is unable to offer flexible contract terms or pushes you to purchase and own the hardware, you will have high total cost of ownership (TCO) and risk holding onto old technology. A pay-as-you-go, OPEX business model is ideal for an IoT application to ensure that you can receive technology upgrades on your device and platform on time.

An additional concern with IoT devices in the supply chain space is managing reverse logistics of the devices since devices here are not the throw away type. In such a scenario, it is wise to ensure that your solution provider can handle the device's reverse logistics.

5. Putting Analytics to Action

A supply chain manager I worked with at a pharma multinational was delighted with the alerts she was receiving about the anomalies of her shipment’s arrival times, unauthorized route deviations, and temperature excursions. However, by the third month, she was frustrated because hundreds of useless alerts were hitting her email box. The alerts were useless because she only had information about what was not right but no information about what she could do to fix it. She began wondering if she had implemented an IoT solution before she and her organization were equipped to handle it. This situation is commonly known as ‘information quantity shock.’ It is important that organizations create plans to address the anomalies that may become visible upon implementing an IoT solution to avoid falling into an information quantity shock.

Setting up small control towers is one good solution. At Roambee, to help customers derive the benefits of an IoT implementation from day one without disruptive organizational changes, we have BeeCentral, a “24x7 control tower” as a service concept. See How BeeCentral works.

Therefore, before implementing a real-time IoT solution, it makes sense to assess the capabilities of your IoT solutions provider across these five pillars. Often pure platform play companies are unable to scale beyond last-mile delivery applications, where proprietary IoT hardware is required. On the other hand, the thousands of companies selling GPS trackers on Alibaba are purely hardware-focused and are unable to provide the analytical power needed to derive real value from monitoring information.

With the increased competition in the IoT arena, it is worth conducting a Request for Proposal or Request for Information (RFP) to better evaluate marketplace options. Even if all your required information is not yet readily available, you will gain additional knowledge and expertise by utilizing strategic and informed comparisons of credible solution providers.