Supply chains have been around way longer than intelligent inventory management software, ERPs, or even computers for that matter, which have all been employed to manage them. Supply Chain Professionals at all levels have to be able to cope with almost anything that’s thrown at them.

With other supply chain solutions already available, why, then, should you embrace the Internet of Things (IoT), digitization, the cost of implementing new asset monitoring systems, and the “potential” benefits these technologies bring to the table?

Quite simply, because you can’t afford

How Are Pharma Supply Chains Unique?

Pharma supply chains, like most other supply chains, grapple with common issues such as supplier management, logistics bottlenecks, cost control, and delivering customer satisfaction. However, as a Pharma supply chain personnel, you also have more complex concerns to think about, such as:

- Product Quality – for fragile consignments that are on the road for periods of time in less than ideal conditions.

- Product Security and Contamination – for shipments requiring “special handling” such as controlled substances that could be siphoned off to manufacture contraband or temperature-sensitive materials whose quality could be compromised.

- Product Availability – because maintaining buffer inventories aren’t always cost-friendly for your logistics or supply chain budgets, especially when you’re holding medical supplies that need very stringent (read 'costly') upkeep.

- Cost and Risk Reduction – whether it’s low-volume high-cost consignments or vice versa, you need to minimize overheads and overspends, especially when you’re trying to meet demanding business requirements without letting it hit your bottom line.

- Liabilities and Litigation – especially when you’re handling controlled substances, materials that could be precursors to controlled substances, or simply trying to ensure nothing sub-par gets stocked on shelves. Whether it’s the war on drugs or counterfeit pharmaceuticals, you don’t want your company to be collateral damage.

These are concerns that transcend divisions.

More often than not, these issues could be overcome through better supply chain visibility, which could, in turn, improve predictability and supply chain efficiency. Improvements to your supply chain are relevant for everyone in your organization from your C-level execs (who are watching the company’s share prices rise and fall, monitoring the bottom line and liabilities that your firm faces), to your CIO (who’d like the data digitization provides to improve productivity), to your Sales & Marketing teams who are concerned about exceeding their annual targets – for which product availability is key.

Supply chain visibility across your enterprise is the first step towards improving customer loyalty, brand reputation, and the ability to foresee issues, but it requires more discipline and data than you think. Very few logistics professionals have complete supply chain visibility, mostly due to a dearth of quality data as well as their reliance on manual tracking processes.

Today, many companies create

Globalization coupled with increasingly complex marketplaces have made handling growing supplier networks more difficult. Finding better alternatives to these are probably on every supply chain professional’s to-do list — especially when markets are competitive and margins slim.

The overheads incurred in warehousing and logistics may sound like the norm, perhaps they’re even accepted as the cost of doing business.

They don’t have to be.

With margins slimming across the industry, your best bet is to bank on technology and data-driven insights that are derived from a digitized supply chain if you’re serious about improving your supply chain’s agility, resilience, security, and adaptability, all of which ultimately help boost productivity, streamline operations, and reduce overheads.

What Can a Digitized Supply Chain Do?

A digitized supply chain is an automated, optimized set of processes that ties your supply chain together end-to-end, and uses data and predictive analytics to improve its performance.

You are probably balancing multiple, sometimes even conflicting business objectives — delaying the fulfillment of an inventory request to avoid shipping sub-products. If you had an enterprise-wide monitoring solution that gave you visibility and predictive analytics across your supply chain, you could be better equipped to deal with this conflict by shipping these goods from an alternative location which might have the stock.

Security, logistics, and transportation all benefit from a digitized supply chain in a global enterprise.

The benefits accrue across your departments/divisions with immediate and transparent ROI that ripples through the entire enterprise and on to the customer’s experience.

Just as your supply chain is the beating heart of your enterprise, data is the lifeblood of your digitized supply chain. For big pharma, it’s not just one piece of data, but the collective intelligence that is important to pharma enterprises, collective intelligence that includes, inventory levels, asset utilization levels, lead time in manufacturing, time/cost benefits, and of course, brand reputation. A digitized IoT enabled supply chain can also provide you with real-time dashboards, improve transportation efficiencies, collate information that helps better decision making, as well as handle a plethora of other tasks that you wouldn’t be able to quite as easily through email and an ERP.

The collective data across divisions allows your digitized supply chain to benefit from what is today known as machine learning, and it effectively provides predictive capabilities for driving growth.

Machine learning is real-time goods monitoring and tracking incorporated into a virtual supply chain. Using real-time monitoring and predictive learning capabilities in the form of machine learning to manage your logistics is very powerful because you are making decisions based on data as against just betting on your best guesstimate – whether it is for security or improved productivity.

All That Sounds Great; So Where Do We Begin Digitizing the Pharma Supply Chain?

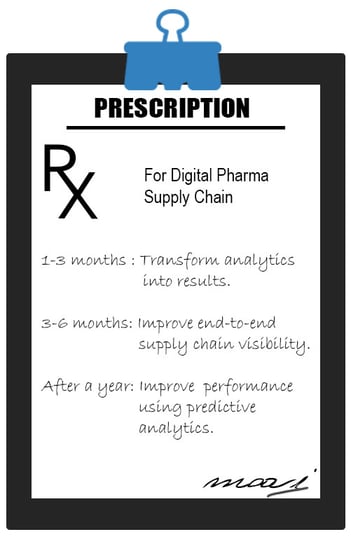

A digitized (or connected) supply chain using predictive analytics is a process

that needs time to evolve within your organization. At the outset, it’s important to align supply chain features/functionality to relevant business needs (lead times, inventory, operations, global processes, productivity) and build it from there. With a working digital supply chain system in place, results will improve with time:

- In 1-3 months, you could transform analytics into results.

- In 3-6 months, you could improve end-to-end supply chain visibility.

- After a year, you could manage your supply chain and improve its performance using predictive analytics.

While there are limitless applications to real-time tracking, in essence, real-time monitoring provides the data you’d need for predictive analytics or machine learning to manage intuitive supply chains.

How Should I Go About Digitizing My Pharma Supply Chain?

When transforming into a digitized enterprise – start with an assessment of your company’s real-time monitoring solution. Often, a company’s monitoring solution is rooted in its security or transportation divisions and is likely a manual set of processes aided by tracking software.

If a lack of visibility is your biggest problem, the three immediate actions you can take when tapping into a fully functioning asset management solution should be:

1. Understand Your Supply Chain

Assess and evaluate your supply chain to identify where visibility is lacking. Unsure where to even begin with that? Start by looking for an IoT firm that understands the supply chain business well.

2. Improve Your Supply Chain

Use IoT and automated goods monitoring tools to start collecting data in order to provide insight and foresight to your supply chain.

3. Connect (Digitize) Your Supply Chain

Data is king, but it needs infrastructure in place that can transform it into alerts and drive last-mile insights, inventory (JIT) assessment, manufacturing needs, transportation routes, and proof of delivery. Once you’ve got the data you need, build and build

It’s easier for a relatively seasoned supply chain professional to assess pain points in the pharmaceutical supply chain (visibility, last mile, route deviations) and how they can be improved upon when they have clarity on their asset monitoring holes. Once you’ve identified the problems, the next step is to develop a point solution for automating and digitizing the supply chain into a fully predictive machine that drives manufacturing, logistics, and even customer experience.

A Digitized Supply Chain Sounds Good, But Who’s Going to Pay for It?

How to measure the benefits — both tangible and intangible — of a digital supply chain is probably one of the first questions you’d ask. How best to justify the cost of a systemic change, demonstrate measurable benefits, and convince stakeholders across the board that it won’t turn into a sunk cost.

To begin with, specific point solutions should have demonstrable ROI as part of their implementation. This is the first step in demonstrating the value of return against cost and make it easy to assess where to apply the initial investment, as well as see the additional benefits that will accrue across the enterprise. Good point solutions are those which can be easily deployed and scaled across your supply chain gradually.

Of course, every company is different. Some pharma companies choose to have their security division implement smart logistics and asset monitoring solutions. In other companies, it is their global supply group (cross-division responsible for enterprise-wide solutions) or in others, it falls to the IT division responsible for innovation implementations. Whichever department you belong to, you can deploy specific point solutions and begin assessing ROI.

Digitization impacts multiple departments and concerns across logistics, supply chain, compliance, security, quality, and brand perception. Roambee’s pharma point solution allows you to start with your warehouse, logistics, or assets, and it can be scaled gradually across your supply chain as you start realizing ROI. Try now!